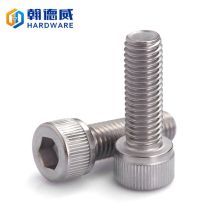

Understanding ISO 4762 UNI 5931 DIN 912 Class 12.9: A Comprehensive Guide

When it comes to selecting the right fasteners for your applications, understanding the specifications and standards is crucial. One such standard is ISO 4762 UNI 5931 DIN 912 Class 12.9. This article delves into the details of this classification, providing you with a comprehensive understanding of its features and applications.

What is ISO 4762 UNI 5931 DIN 912 Class 12.9?

ISO 4762 UNI 5931 DIN 912 Class 12.9 refers to a specific grade of hexagon socket cap screws. These screws are designed to provide high tensile strength and resistance to wear and fatigue. They are commonly used in various industries, including automotive, aerospace, and construction.

Material and Dimensions

Class 12.9 screws are typically made from high-strength steel, which is heat-treated to achieve the desired properties. The material used is often specified as AISI 8740 or similar grades. The dimensions of these screws follow the ISO 4762 standard, which defines the thread size, length, and head diameter.

| Thread Size | Head Diameter | Length |

|---|---|---|

| M10 | 16mm | 50mm |

| M12 | 18mm | 60mm |

| M14 | 20mm | 70mm |

Properties and Applications

Class 12.9 screws offer several advantages that make them suitable for demanding applications. Here are some key properties and their corresponding applications:

- High Tensile Strength: These screws can withstand high tensile loads, making them ideal for heavy-duty applications.

- Excellent Fatigue Resistance: The heat-treatment process enhances the fatigue resistance of these screws, ensuring long-lasting performance.

- Corrosion Resistance: While not as corrosion-resistant as stainless steel screws, Class 12.9 screws can be coated or plated to improve their resistance to corrosion.

Applications of Class 12.9 screws include:

- Automotive components, such as engine mounts and suspension parts

- Aerospace structures, such as aircraft frames and landing gear

- Construction equipment, such as cranes and excavators

- Heavy machinery, such as mining equipment and industrial presses

Installation and Maintenance

Proper installation and maintenance are essential to ensure the longevity and performance of Class 12.9 screws. Here are some tips:

- Use the Correct Torque: Over-tightening can lead to thread stripping, while under-tightening can result in loose connections. Always follow the manufacturer’s recommended torque specifications.

- Use the Right Tools: Specialized tools, such as torque wrenches and socket sets, are designed to ensure proper installation and prevent damage to the screws.

- Regular Inspection: Periodically inspect the screws for signs of wear, corrosion, or damage. Replace any worn or damaged screws to maintain the integrity of the assembly.

Conclusion

ISO 4762 UNI 5931 DIN 912 Class 12.9 screws are a reliable choice for demanding applications that require high tensile strength and fatigue resistance. By understanding their properties, dimensions, and applications, you can make informed decisions when selecting fasteners for your projects.